Comprehensive Overview to RainierGPR Concrete Scanning Techniques

Harness the Strategic Side of Concrete Scanning for Unparalleled Task Success and Top Quality Guarantee

In the realm of modern building and construction and framework advancement, the application of concrete scanning technology has actually arised as a critical device for guaranteeing job success and preserving high quality standards. The true power of concrete scanning lies not just in its ability to enhance job outcomes but likewise in its capacity to change traditional techniques, setting a brand-new criteria for accuracy and effectiveness in the construction sector.

The Value of Concrete Scanning

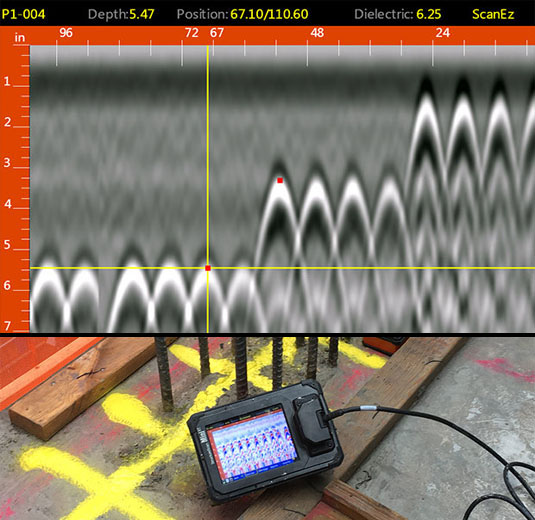

Concrete scanning is a necessary action in building and construction jobs to ensure the safety and security and stability of frameworks. By using different scanning technologies such as Ground Passing Through Radar (GPR) and electro-magnetic induction, construction groups can non-destructively examine the subsurface of concrete structures to determine possible risks like rebar, conduits, or post-tension cables. This info is critical for task supervisors, specialists, and designers to make enlightened choices and prevent expensive mistakes during the building process.

One of the main reasons concrete scanning is so crucial is its ability to stop accidents and injuries on the construction site. Mistakenly cutting via a live electrical channel or destructive post-tension cables can have devastating repercussions, not only in regards to safety and security but likewise in regards to job delays and monetary effects. By carrying out detailed concrete scanning prior to any boring, reducing, or coring tasks, building groups can mitigate risks and develop a more secure working setting for everyone included.

Along with safety and security considerations, concrete scanning additionally plays an essential function in making sure the long-lasting durability and top quality of the framework. By finding any type of anomalies or problems concealed below the surface area, such as gaps or delamination, very early intervention can be executed to deal with these concerns before they intensify right into more substantial issues. Inevitably, spending in concrete scanning is a positive step that can save time, money, and sources over time, while additionally supporting the highest possible criteria of construction excellence.

Advanced Innovation for Exact Outcomes

By incorporating these innovative modern technologies right into concrete scanning methods, building groups can enhance process, minimize project hold-ups, and make certain the overall high quality and success of the task. The accuracy and performance used by these devices add substantially to the task's success by assisting in informed decision-making and developing quality assurance actions.

Enhancing Task Performance and Timelines

Furthermore, concrete scanning allows groups to determine architectural weak points and possible risks early on, enabling timely removal and preventing accidents that might hinder task timelines. The real-time data offered by scanning devices promotes informed decision-making, resulting in smoother control amongst different trades and stakeholders. This boosted cooperation lessens conflicts, improves efficiency, and go to this web-site eventually speeds up job shipment.

Moreover, by proactively resolving concerns with concrete scanning, building groups can follow routines much more successfully, minimize downtime, and enhance source allowance. The capability to identify hidden obstacles and verify structural integrity my latest blog post efficiently contributes to general job effectiveness and timelines, making sure successful outcomes and client complete satisfaction.

Ensuring Safety And Security and Risk Reduction

Risk mitigation techniques can be improved through the detailed info given by concrete scanning, enabling job groups to make informed choices that minimize the likelihood of unexpected incidents. reference In addition, by accurately drawing up subsurface conditions, professionals can stay clear of costly rework, hold-ups, and damage to existing frameworks, better adding to general task safety and success. Carrying out concrete scanning as a regular method not just makes sure a much safer job setting but also imparts confidence in stakeholders relating to the task's dedication to top quality and risk management.

Quality Control Via Concrete Scanning

Concrete scanning plays a critical role in promoting quality control requirements within building and construction jobs. By making use of advanced scanning innovations such as Ground Passing Through Radar (GPR) and Concrete X-ray, project managers and engineers can ensure the stability and quality of concrete frameworks. With concrete scanning, potential flaws, such as voids, fractures, or strengthening bar blockage, can be identified non-destructively, enabling prompt treatments to preserve the structural honesty of the job.

Quality guarantee through concrete scanning not just helps in identifying existing issues but also makes it possible for aggressive steps to avoid future issues that can jeopardize the safety and security and longevity of the structure. By conducting detailed scans at key stages of building, groups can verify the precision of structural strategies, validate the positioning of critical elements, and resolve any inconsistencies without delay. This positive method minimizes rework, minimizes expensive hold-ups, and ultimately causes the distribution of high-grade, long lasting frameworks that fulfill or surpass sector criteria.

Final Thought

In conclusion, concrete scanning plays a vital duty in ensuring job success, safety, high quality, and efficiency guarantee. The tactical edge given by concrete scanning allows for positive threat mitigation and enhances general project administration.

In the realm of modern-day construction and framework growth, the application of concrete scanning innovation has emerged as a pivotal device for making certain job success and maintaining top quality criteria. By incorporating these advanced modern technologies right into concrete scanning practices, building and construction teams can enhance process, reduce project hold-ups, and make certain the total quality and success of the task.Given the vital nature of task performance and timelines in building monitoring, the emphasis now shifts towards ensuring security and mitigating risks within the project setting.Concrete scanning plays a critical function in upholding top quality guarantee requirements within building tasks. By making use of innovative scanning innovations such as Ground Passing Through Radar (GPR) and Concrete X-ray, task managers and engineers can make certain the stability and high quality of concrete frameworks.